3D printing technology has revolutionized numerous industries by offering unparalleled flexibility, speed, and customization capabilities.

Unleashing Creativity in Packaging Design

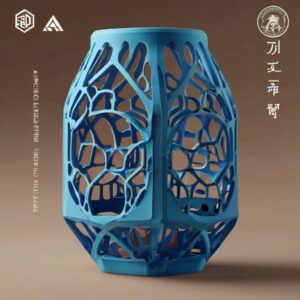

The advent of 3D printing has revolutionized the field of packaging design, transforming it into a realm where the only limit is the designer’s imagination. No longer held back by the cost-prohibitive and time-consuming molds required for traditional manufacturing, designers are now diving into the exploration of shapes and forms that would have been considered too intricate or too avant-garde. This technological shift allows for the creation of packaging that is visually captivating and uniquely tailored to embody the essence of a brand and opens up a lot of possibilities in improving user interaction. From ergonomic grips that enhance the handling experience to smart closures that add a layer of convenience, the focus has expanded beyond aesthetics to include functional innovation. The environment benefits as well, with opportunities to use more sustainable materials or designs that minimize waste. Packaging is increasingly becoming a multidimensional component of the product, contributing to branding, sustainability, and user satisfaction, paving the way for a new era of consumer engagement.

Sustainability at the Core

Unlike conventional manufacturing processes, which often involve the subtractive method of removing material to create a shape and thereby producing a significant amount of waste, 3D printing adopts an additive approach. This method precisely layers material only where it’s needed, dramatically reducing the surplus and inefficiency that have long plagued packaging production.

This precision and efficiency extend beyond just the minimization of waste. The scope of materials compatible with 3D printing technologies is vast and growing, encompassing an array of options that include not only biodegradable materials but also innovative composites made from agricultural waste and other renewable resources. These advancements enable businesses to push the boundaries of what’s possible in sustainable packaging solutions, providing the freedom to design packages that are not only functional and visually appealing but also kind to the planet.

The adaptability of 3D printing techniques supports small-batch production runs, allowing for customization and localization without the environmental toll associated with mass manufacturing. This means companies can produce exactly what is needed, where it is needed, decreasing the carbon footprint of their packaging by eliminating the need for long-distance transport of large inventories.

The integration of 3D printing into the packaging sector signals a transformative shift towards sustainability, offering a tangible way for companies to demonstrate their commitment to environmental principles. By leveraging this innovative technology, businesses can achieve a harmonious balance between fulfilling consumer demands, enhancing brand appeal, and upholding their responsibility to the planet, ultimately contributing to a more sustainable future for all.

Customization at Scale

One of the most exciting advantages of 3D printing is the ability to customize products at scale. In the context of packaging design, this means that brands can offer personalized packaging options to their customers, enhancing the unboxing experience and creating a deeper emotional connection with the product. This level of personalization was previously unthinkable, reserved for luxury items due to the high costs of traditional manufacturing methods for small batch runs.

Now, 3D printing makes it economically viable to produce even single units of personalized packaging, opening up new avenues for product differentiation and customer engagement. This trend is particularly pronounced in industries such as cosmetics, electronics, and specialty foods, where packaging plays a crucial role in the brand experience.

Enhanced Functionality and Accessibility

Beyond aesthetics and sustainability, 3D printing is used to enhance the functionality of packaging. Innovative designs that incorporate moving parts, such as self-locking mechanisms or built-in dispensers, can be produced without the need for assembly, reducing labor costs and complexity. Such advancements not only improve the user experience but also the efficiency of the packaging process.

3D printing has the potential to make packaging more accessible. For instance, designs can be easily adapted to include braille, ergonomic features for those with limited manual dexterity, or even shapes that are easier for the visually impaired to recognize. This inclusive approach to packaging design underscores the technology’s ability to meet diverse consumer needs.

The Future of Packaging Design

The possibilities of 3D printing in packaging design are only set to expand. As the technology continues to advance, we will see even more innovative materials, faster printing speeds, and larger print sizes, all of which will further broaden the horizons of what’s possible in packaging.

As 3D printers become more widespread and accessible, small businesses and individual designers will have the opportunity to disrupt the market with unique packaging ideas. This democratization of design could lead to a surge in creativity and innovation, challenging larger players to think differently and pushing the entire industry forward.

The transformation of packaging design through 3D printing is not just a trend but a fundamental shift in how we think about packaging. From unleashing creativity and pushing sustainability forward to enabling unprecedented customization and enhancing functionality, 3D printing is redefining the role of packaging in the consumer experience.